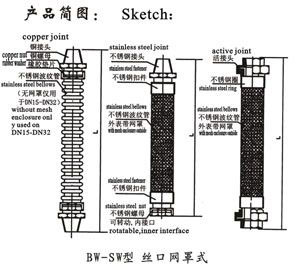

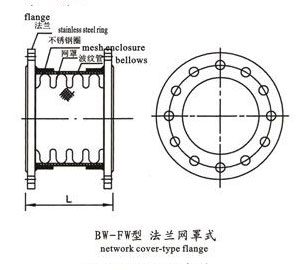

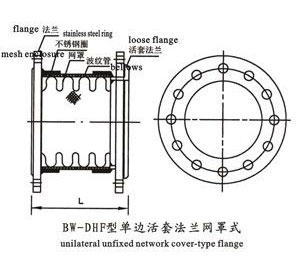

BW型通用型不锈钢金属软管主要由波纹管、网套和接头(法兰或活接头)等部件组成。适用于管道工程系统中为补偿位移和安装偏差、吸收振动及降低噪声等所采用,根据工程需要可适当延长和缩短制造长度。由于软管的弹性体波纹管的材料是奥氏体不锈钢,因此具有良好的柔软性和耐曲挠性,很容易吸收各种交变运动和载荷,抗疲劳性强、耐压高、耐腐蚀、耐高低温(-200℃-600℃),广泛用于航天、航空、船舶、化工、石油、电力、冶金、造纸、纺织、军工、建筑、医药、食品、交通运输等行业。当温度、介质变化大时,需考虑温度与压力的递减系数,除表中所列材料外,其他特殊铁系、镍系、合金钢的压力递减系数请接洽本公司。

BW-based general-purpose stainless steel metal hose is mainly consisted of bellows, net sheath and joint (flange or active joint) etc. It is used in the system of pipeline project for compensating displace-ment, installing distortion, vibration absorber as well as muffling, the length of which can be adjusted according to the need of the project. Since the corr-ugated soft pipe is made up of austenitic stainless steel, it has the best pliability and flexibility and is easy to absorb the distortion caused by movement and weight. It is widely used in the field of spacef-light, aviation, shipping, chemical industry, oil, electric power, metallurgy, paper making, textile, war industry, construction, medicine, food, traffic and transportation etc. When the temperature and medium changes greatly, the temperature and descend-ing coefficient of pressure should be taken into consideration. Apart from the material listed in the table, please contact us if you need the descending coefficient of pressure of other special material such as iron, nickel or alloy steel.

温度、材料、压力递减系数表

table of descending coefficient of pressure, temperature, material

| 材料 material | SUS321 | SUS316L | SUS304 |

| 温度temperature | |||

| -200-50 | 1.00 | 1.00 | 1.00 |

| 100 | 0.96 | 0.94 | 0.93 |

| 150 | 0.92 | 0.90 | 0.89 |

| 200 | 0.88 | 0.86 | 0.84 |

| 250 | 0.84 | 0.82 | 0.79 |

| 300 | 0.80 | 0.78 | 0.74 |

| 350 | 0.76 | 0.74 | |

| 400 | 0.72 | 0.70 | |

| 450 | 0.66 | ||

| 500 | 0.60 | ||

| 550 | 0.54 | ||

| 600 | 0.44 |

各种酸碱选材表

selecting table of all kinds of acid and alkali

| 温度temperature | 30°C | 接近沸点 near boiling point | 中间温度 mid temperature |

| 介质 medium | |||

| 硝酸 nitric acid | SUS304 | SUS304 | SUS304L |

| 硫酸 sulfuric acid | SUS316 | Incoloy825 | Incoloy825 |

| 亚硫酸 sulfurous acid | SUS316 | SUS316.317 | SUS316.317 |

| 醋酸 acetic acid | SUS304.316 | SUS316.317 | SUS317.114ML |

| 磷酸 phosphoric acid | SUS304 | SUS316.317 | SUS317L. Incoloy825 |

| 盐酸 hydrochloric acid | SUS316 | Incoloy825 | Incoloy825 |

| 碱 alkali | SUS304 | SUS304.304L | SUS304.347 |

| 氨 ammonia | SUS304 | SUS316 | SUS316.316L |

| 盐水 salt water | SUS036L | SUS317.M-5 | Incoloy825 |

常用波纹管材质

common material of bellows

| 名称name | 牌号Shopsign | 使用温度°C working temperature °C | 标准号standard No. |

| 奥氏体不锈钢austenitic stainless steel | ocr18Ni10Ti(sus321) | -200~550 | GB/T4237? GB/T3280 |

| ocr17Ni12Mo2(sus316) | |||

| ocr18Nig(sus304) | |||

| oocr19Ni10(sus304L) | -200~425 | ||

| oocr17Ni14MO2(SUS316L) | -200~450 | ||

| 耐蚀合金corrosion resistant alloys | NS111 | -200~700 | GB/T15010 |

| FN-2 | CB1330 |

几种介质选材表

selecting table of all kinds of medium

| 材料 material | 可使用的材料 material available | 优良材料 excellent material |

| 介质 medium | ||

| 普通水 water | SUS304 | SUS316 |

| 海水 seawater | NTKM-5 | Incoloy825 |

| 蒸汽 steam | SUS316L | SUS316L |

| 原油 crude oil | SUS316L | NTKM-5 |

| 轻质油 light oil | SUS316 | SUS316L |

| 重油 heavy oil | SUS304 | SUS316 |

| 锅炉排气高温 high temperature for boiler exhaust | SUS304 | SUS316L |

| 低温 low temperature | SUS316L | Incoloy825 |

| 柴油机排气 diesel exhaust | SUS304 | SUS316 |

| 粗制进炉气 crude gas into the furnace | SUS316L | Incoloy825 |

| 精制焦炉气 refining gas into the coke oven | SUS316 | SUS316L |

| 高炉气 blast furnace gas | SUS304 | SUS316 |

| 烧切炉排气 tangential firing furnace exhaust | SUS316 | SUS316L |

| 船舶甲板蒸汽管 ship deck steam pipe | SUS316L | Incoloy825 |

| 船舶低温液化气管 ship low-temperature liquefied gas pipe | SUS316L | SUS316L |

| 空气 air | SUS304 | SUS304 |

| 低温氧气 low-temperature oxygen | SUS304 | SUS316L |

| 高温氧气 high-temperature oxygen | SUS316 | SUS316L |

技术特性表

technical characteristics table

| 公称通径mm nominal diameter | 长度mm length | 波纹管有纹面积cm2 lined area of bellows | 最小弯曲半径(动态)mm min. bend radius (dynamic) | 径向最大变化量mm max. radial displacement | |

| 法兰联接 flange join | 15 | 200 | 3 | 120 | 30 |

| 20 | 200 | 3.5 | 170 | 30 | |

| 25 | 200 | 9 | 200 | 30 | |

| 32 | 200 | 19 | 250 | 30 | |

| 40 | 200 | 21 | 250 | 30 | |

| 50 | 250 | 41 | 350 | 20 | |

| 65 | 250 | 61 | 410 | 20 | |

| 80 | 250 | 82 | 450 | 20 | |

| 100 | 250 | 125 | 560 | 20 | |

| 125 | 280 | 180 | 660 | 20 | |

| 150 | 280 | 255 | 815 | 20 | |

| 200 | 280 | 480 | 850 | 20 | |

| 250 | 300 | 730 | 950 | 20 | |

| 300 | 300 | 1020 | 1400 | 25 | |

| 350 | 300 | 1280 | 1500 | 25 | |

| 400 | 350 | 1580 | 1800 | 25 | |

| 450 | 350 | 1980 | 2000 | 30 | |

| 500 | 400 | 2450 | 2400 | 30 | |

| 600 | 400 | 3450 | 2800 | 30 | |

| 700 | 400 | 4740 | 3000 | 30 | |

| 800 | 450 | 5960 | 3200 | 30 | |

| 丝口联接 interface join | 15 | 250 | 3 | 160 | 30 |

| 20 | 250 | 3.5 | 200 | 30 | |

| 25 | 250 | 9 | 220 | 30 | |

| 32 | 250 | 19 | 280 | 30 | |

| 40 | 300 | 21 | 280 | 20 | |

| 50 | 300 | 41 | 400 | 20 | |

| 65 | 300 | 61 | 500 | 20 | |

| 80 | 300 | 82 | 700 | 20 | |

以上为工作压力1.0Mpa之参数,1.6Mpa产品弯曲半径放大约20%,径向最大变位量缩小约20%,2.5Mpa产品弯曲半径放大约40%,轴向伸缩量按照长度根据压力大小取3~5%,但安装时应按原始长度取值,产品伸缩时会产生网罩鼓胀和凹瘪现象。

Note:The parameter mentioned above is under 1.0Mpa working pressure. Under 1.6Mpa working pressure, the bend radius will be magnified about 20% and max. Radial displacement will shrink about 40% while the bend radius will be magnified about 20% when the working pressure is 2.5M.The axial displacement is 3~5% according to length and pressure but it is the original length value when installed. The displacement of the product will caused the reticulation expanding or concave.

ZTA、ZTB、ZTC型阻尼弹簧隔振器

ZTD、ZTI型阻尼弹簧大载荷隔振器

ZTE型阻尼弹簧隔振器

ZTF型阻尼弹簧隔振器

ZTG型可调式低频弹簧隔振器

LQT型金属弹簧隔振器(冷却塔专用)

DND大挠度金属弹簧隔振器

FXG型非线性金属弹簧隔振器 GSF型钢丝绳隔振器

ZDH、ZHS、VHS型吊式阻尼弹簧隔振器

YDS型弹簧隔振器

KT型空气弹簧隔振器

WHD型吊式橡胶隔振器

RM型橡胶隔振器 BE型橡胶隔振器(船用)

JG型橡胶剪切隔振器 JSD型低频橡胶隔振器

GDJ、T型橡胶隔振器 SPR抗冲击液压缓冲器

YZT型橡胶隔振器(电子仪器仪表用)